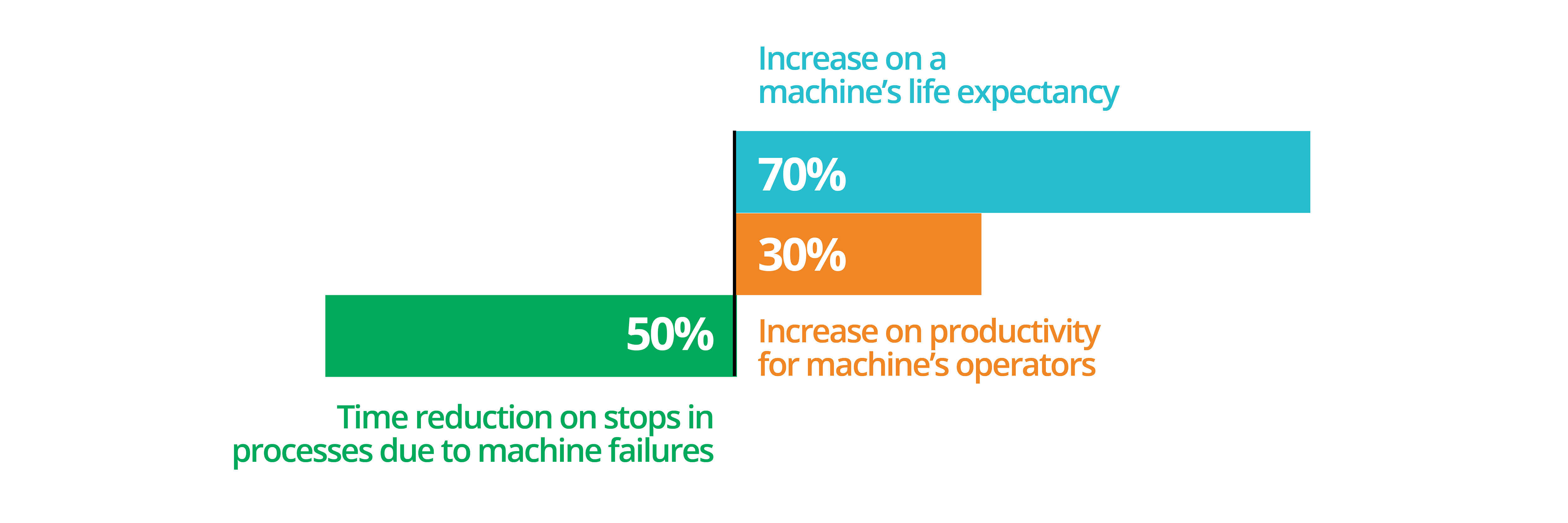

4TUNA is an Ecuadorian start-up that provides an enterprise asset management platform, which extracts and delivers information about the operational state of industrial machines. They provide the people who manage this equipment with real-time information to prevent failures and outages, optimizing life expectancy, availability and efficiency of industrial machinery through technology.

This start-up grew exponentially because of their innovative value proposition, generating a wide portfolio of clients, so they needed to scale to meet increased customer demands.

4TUNA’s challenge was that despite understanding their customers' requirements, they were unable to scale the solution quickly because of the lack of qualified developers to evolve their technology platform. So, to find a partner to help them to move forward, they applied to the Prototype Lab initiative of Thoughtworks Ecuador, and won the chance to work with our teams for 2 months.

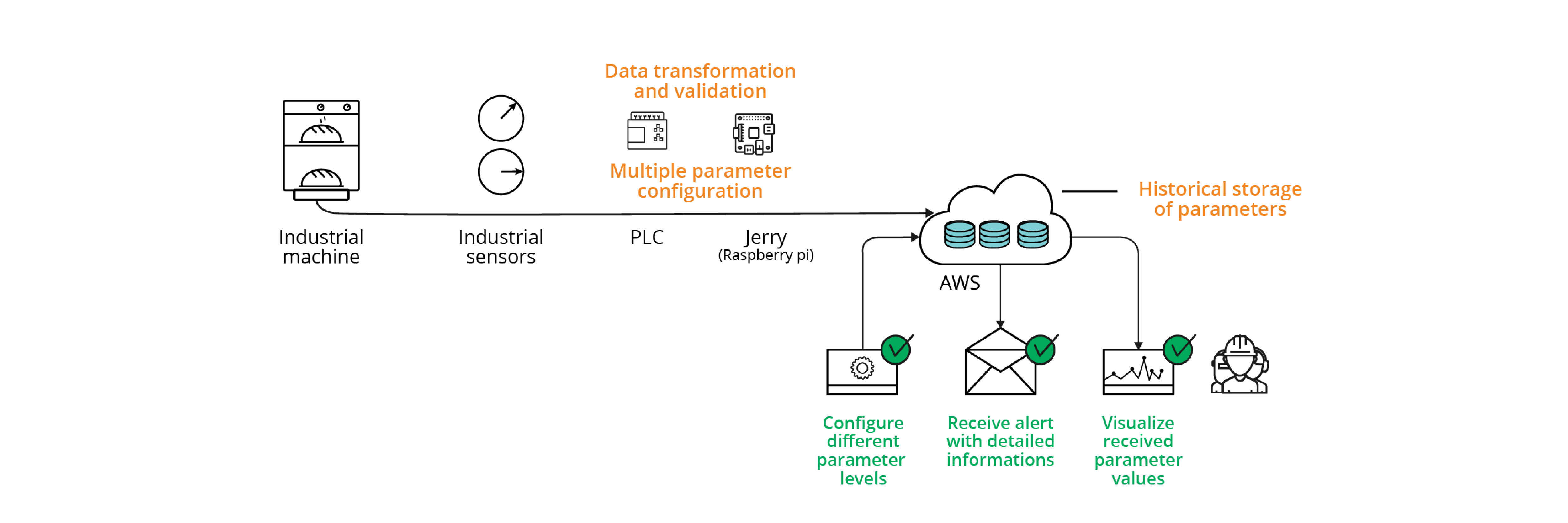

Working together, 4TUNA and Thoughtworks built upon the existing foundation to create a solution that combined hardware and software components through the use of IoT and Big Data technologies.

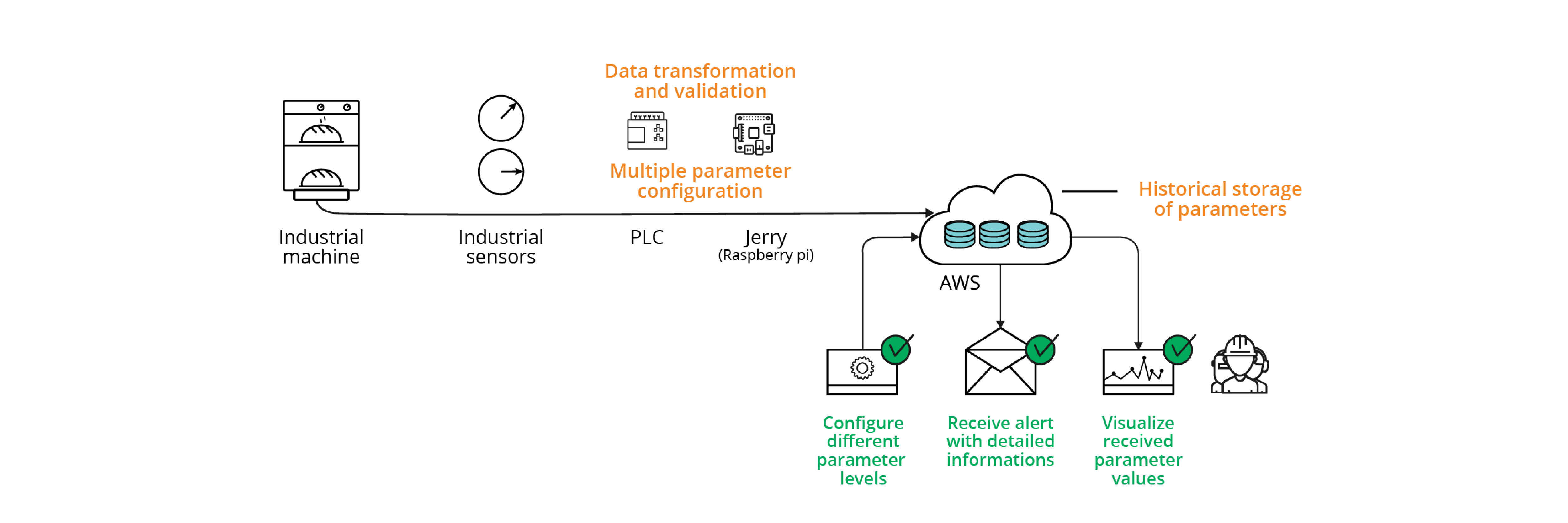

Currently, industrial machines have sensors connected to programmable logic controllers (PLC’s) that recollect information of parameters, such as temperature and pressure level. We created a “machine to customer” experience with the PLC’s, using a raspberry pi computer board to validate and transform the data collected by the PLC to send it to the cloud. That means that the hardware was in charge of sending the information from time to time, transforming and validating the data without human intervention. 4TUNA sends alerts to technicians and operators when it detects that the operating values are not in the expected range, allowing them to take proactive actions and avoid possible failures. The historical information of all these parameters are stored so that machine operators can view them and over time these could be used as a predictive tool for future fault detection. This information is sent to the cloud that we implement with AWS and an "infrastructure as code" approach.

Together with Thoughtworks, we grew in 2 months what would have taken us a year. We laid the foundations for being an agile team, we learned the value of prototypes and short iterations, we learned to work remotely and to value agile ceremonies. Thanks to this we are now better prepared to succeed with our product.

Results

Since the project ended in 2019, 4TUNA has collected and analyzed more than 100 million readings of variables from different machines and protocols using our IoT solution. 4TUNA has detected and sent more than 1000 alerts in real time of deviations, reducing by 60% the risk of failures in the machines.