oOh!media is a leading out-of-home advertising operator across Australia and New Zealand with a portfolio of classic and digital location-based signs across retail, roadside, and airport. They provide clients with greater connections and engagement with their own customers.

Thoughtworks partnered with oOh!, introducing practical lean techniques to help identify opportunities to remove inefficiencies from their internal business processes and increase their capacity for work that adds value to the business. Together, we performed a detailed value stream analysis by mapping the entire end-to-end customer journey from sales through to contract and campaign delivery. Using the value stream map as a high-resolution picture of the current state, we built a joint understanding of where efficiency and/or quality could be improved.

In addition to the process improvement activities, Thoughtworks guided the content creation teams through the re-engineering of their product development process. Together with oOh! we embedded both lean and agile principles - like robust process controls and iterative design loops - in the new process to increase the quality of the work. We established a continuous improvement plan for the new process to allow new and better ideas to be quickly tested.

To establish a culture of continuous improvement, Thoughtworks lean coaches delivered a series of tailored and engaging workshops to a core team of people from all areas of oOh!. After learning new tools and practices, and covering the key fundamental concepts of lean value and waste in the context of oOh!’s own ecosystem, the new lean team was able to better identify and describe problems and develop improvement experiments to test their ideas under the guidance of our coaches.

I sense an energy and enthusiasm: we had silos in the past but now people from across the department are coming together to solve problems.

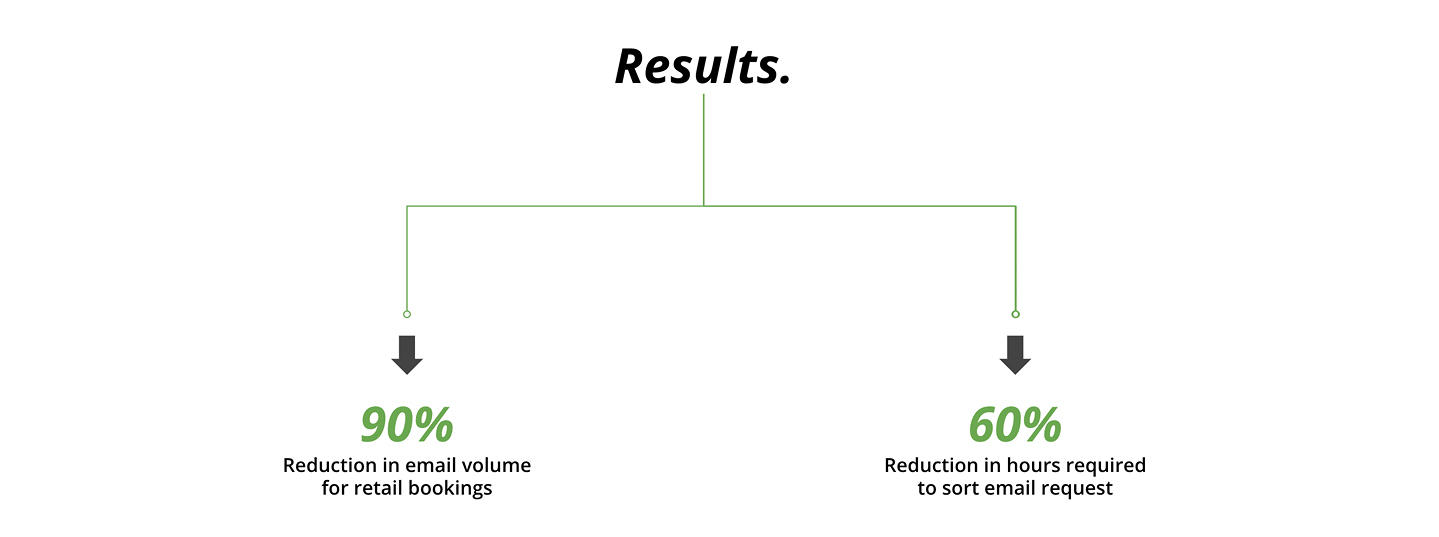

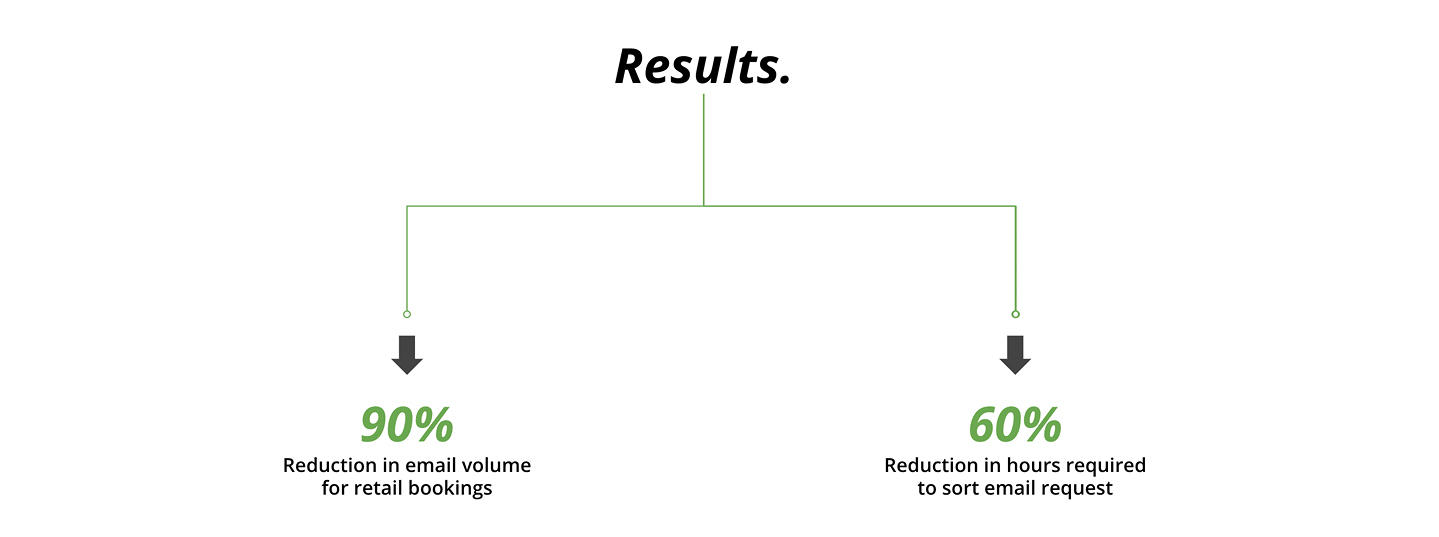

Implementing a true lean mindset across the business - the identification and steady elimination of waste - has allowed the core team and champions to have a significant impact in just a few weeks. For example, a standard template to structure information hand-offs between the sales and retail teams reduced the average number of emails required from nineteen to two. Improvements to the contract booking process will reduce the need for rework and waiting time, removing roughly nineteen hours of waste per day. Another improvement saw the implementation of automatic rules for filtering incoming email requests, reducing the time needed to sort email from one hour per person per day to ten minutes per person per day.

It was important to leave the lean champions with the ability to cultivate self-sustaining continuous improvement to inform and encourage other employees and ultimately delight end-customers. We used a ‘train the trainer’ approach, allowing the champions to build new advocates for lean within the business. Together with a Thoughtworks continuous improvement kit, the lean champions are now able to teach lean principles and run practical activities to spread the knowledge and skills throughout the organization.

Rather than come in with a predefined plan, Thoughtworks collaborated with the oOh! Media team to develop an approach tailored to each specific problem. This iterative approach allowed the team to learn, adapt and refine along the way as new information was uncovered. A fantastic way of working!