For retailers worldwide, the COVID-19 pandemic has highlighted the most fragile and risk-heavy areas of their supply chains — from cross-geography supplier dependencies to outsourced services, and even in-house workforces.

Supply chain isn’t just the lifeblood of retail, it’s also highly complex. As the robustness of both everyday operations and contingency plans have been put to the test, improving the future resilience of supply chains has become a priority for every retail boardroom.

Even during the best of times, the supply chain is a key center of outsourced, hard-to-control costs and risks, that can be impacted by everything from the weather, to driver sickness and traffic congestion. Retailers that improve their supply chain functions stand to enhance both their supplier and partner relationships — and their bottom line.

With many supply chains still facing a bullwhip effect, understanding the powerful lessons of the pandemic is urgent — and the smartest retailers are already beginning to act.

They’re asking questions like these:

- Should we collaborate more closely with our suppliers?

- What new risk controls and processes should we adopt?

- Are our operations as cost-effective as they could be?

- Is our distribution strategy — and distributed physical presence — working well?

- Have we made the right trade-off between efficiency and stability?

- Do we have the right balance between lean sourcing and multi-sourcing?

- Is our supply chain truly demand-driven? Can we predict demand with sufficient accuracy?

- And, of course, “What do we need to thrive in this new normal?”

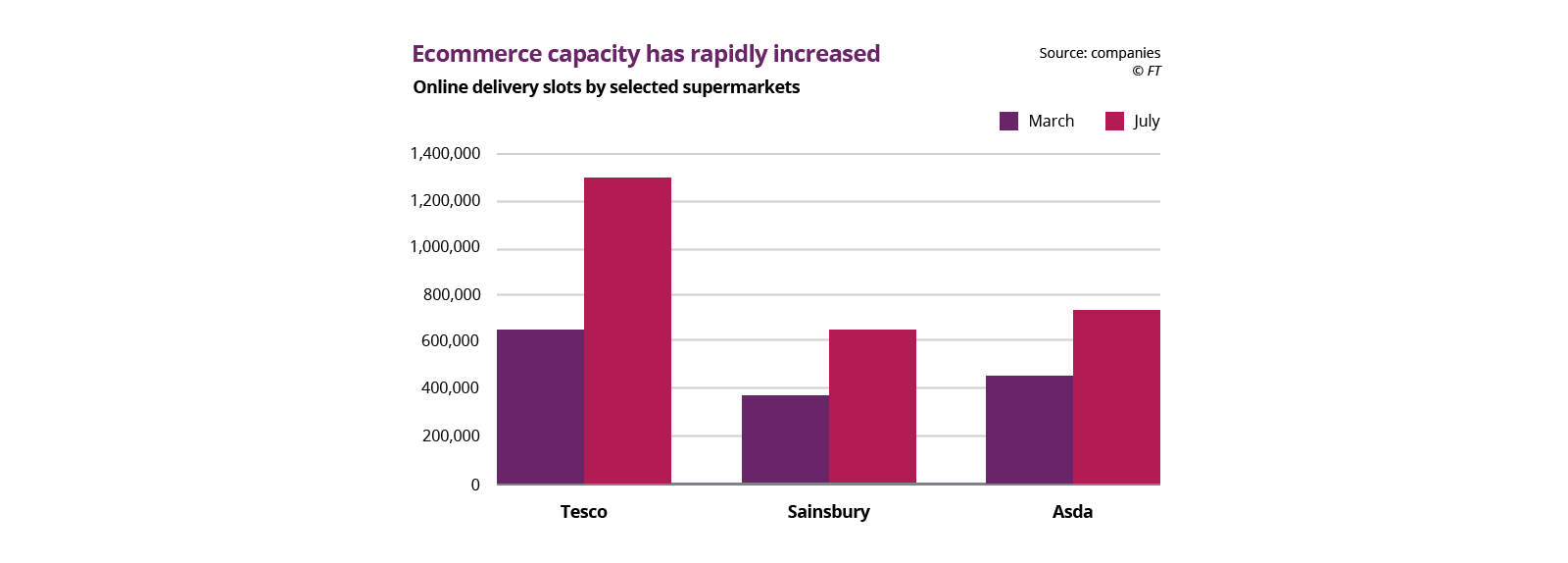

This final question is key. It’s important retailers learn the lessons of COVID-19 and improve their preparedness for future adversity. Part of building this resilience also involves rethinking the very nature of their supply chain in the context of an increasingly digital consumer landscape. According to the latest report by Alvarez & Marsal, 25% of the UK's total population are permanent online consumers and this is only set to increase in a remote-first world.

In this article, we’ll drill down into the supply chain lessons retailers can take from the pandemic.

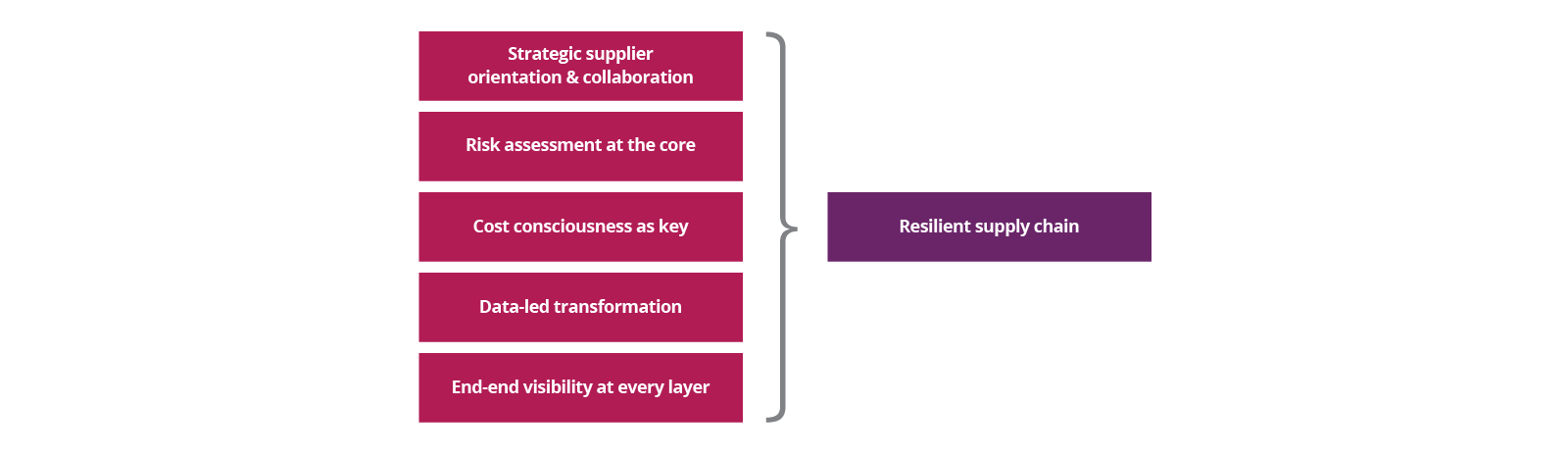

The five imperatives for a resilient supply chain

We believe there are five critical issues to address in your supply chain. Few retailers have previously focused on these areas; today all of them require continuous attention.

Strategic supplier orientation and collaboration

Most retailers already have strong relationships with their suppliers, as well as with their freight, transportation and emergency outsourcing partners. But to improve supply chain resilience, you’re going to have to build on these connections, to drive transparency and increase understanding and collaboration.

Clean and clear supplier management is vital. This means formalizing supplier orientation, assessment and relationship models with each of your supplier segments. For many, diversifying and prioritizing suppliers will be key. Revisiting inflexible, just-in-time, sourcing strategies will also be a priority.

At the same time, retailers, suppliers and partners must get to know each other like never before. Traditionally, all parties have been hesitant to proactively share their annual goals, their forecasts, their product performance data and their revenue opportunities. Now is the moment to learn to open up dialogues, connect digitally and collaborate end-to-end for mutual success. This means aligning organizational goals, sharing contingency and business continuity plans, and striving for transparency of execution — at all levels.

If you work with your supplier networks in this way, you stand to develop true win-win propositions: growing sales categories, increasing distribution efficiency and product availability, and improving merchandising operations.

Risk assessment at core

Many retailers have, until now, seen risk assessment as a yearly or twice-yearly necessity. But the COVID-19 crisis has brought the ever-present nature of supply chain risks into sharp focus.

And it’s not just the risks posed by unforeseen external factors that you must consider. It’s also the risks posed by known and manageable factors inside your business. Identifying the vulnerabilities (process, compliance, technology, logistics and workforce) in your end-to-end supply chain planning and operations — and the impact on business metrics — may be complicated work, but it’s vital. As, of course, is identifying ways to mitigate those risks.

You can choose to assess supply chain risk in a number of ways. One is to focus on your different functions and tiers, from your supplier network to your inventory plan, outsourced services, logistics, warehouse operations and distribution.

Another is to use data to identify risk factors. These risk factors can be explored and managed based on hypotheses. A good first step is for your planning teams to design “What if?” risk scenarios and assess that impact on operations and execution.

For example, they might ask: “If demand surges by X%, do we have the inventory and workforce to meet it?” This might prompt other questions for other functions, like “Logistically, could we cater for a Y% increase in online orders in the next five days?”

Asking these kinds of specific questions is great for raising the profile of supply chain risks — and spurring the creation of contingency plans.

Reassess your supply chain cost-bases

Recent scenarios have brought supply chain costs to the limelight. Many grocers in the UK have highlighted that the significant additional costs incurred during the COVID-19 pandemic are hitting their profits.

Retail supply chains are generally cost-intensive. Which aspect of that supply chain is most costly will vary from retailer to retailer, depending on their business and operating model. But many — especially those that have been in business for decades — find it difficult to understand the true cost of moving individual products from one end of the supply chain to the other and how the cost is allocated for different stages. This inhibits their ability to make effective commercial decisions.

Too often, retailers’ various functions act independently to reduce costs — apparently fixing the problem but creating unseen side effects for another function. For instance, your central store-ordering operations team might choose to control ordered quantities to reduce truck movement costs per day. But if this new strategy impacts the availability of stock in store, it could create ad hoc distribution costs instead. Hence, it’s important to take an overarching view of the supply chain to fully appreciate the problems and opportunities that exist. A holistic view allows for overall system-wide solutions to be developed; solutions which are cognizant of the flow across multiple functions and enable each party to address cost, efficiency and risk.

Last-mile fulfillment is a common cost-base for retailers. Many have already taken steps to strengthen their capability in this area, using dark stores, micro-fulfillment centers and stores as distribution centers (see Alibaba-Hema Stores, Amazon’s Whole Foods, Kroger, etc.) Now may be the time to explore more sensitive cost-reduction strategies, such as asking customers whether they would be happy to receive their order split across two deliveries or to receive their weekly shop fortnightly — while always being careful not to damage customer satisfaction. For instance, Alibaba incentivizes customers to accept delivery of hot and fresh food within 30 minutes, with non-fresh food arriving later.

Another common cost is the freight cost of loading up warehouses. Even before the COVID-19 pandemic, truck demand in the US had been increasing 150% year on year. Here, retailers can consider new sourcing strategies, such as switching to local suppliers capable of delivering goods direct to store or direct to customers from the suppliers’ distribution centers. Alternate options could be to find opportunities to reduce product assortment or to combine shipments for certain product lines, optimized delivery slots for customers for reduced delivery charges, split distribution, etc. that not only reduces costs but also carbon footprint.

Data-led transformation

As we’re well aware, every retailer is at a different stage of evolution toward a data-driven supply chain and for many, some functions are more advanced than others. Whether this is due to functions driving their own data strategy or being forced to deploy specific solutions to keep pace with the industry, such disconnected efforts will offer limited value in the longer term. According to a recent survey by Ericsson of 2,000 logistics professionals from Germany, United States, Sweden and China, about one-third of respondents said their inability to quickly share accurate information between customers and suppliers is a roadblock for their business.

A holistic approach is key. Retailers who can complete the transformation from partially to fully digital operations will gain real-time visibility, make smarter decisions and in the long term, be better positioned to realize the benefits of process automation.

Outside ‘business-as-usual’, data now enables an increasingly forward-looking approach. For example, ‘What-If analysis’ can be leveraged for identifying risks and vulnerabilities in the supply chain. To take a simple example, you can simulate the flow of specific quantities of stock to a specific group of stores versus another, and then predict the impact on sales and cost in order to make a better commercial decision.

At the moment, few retailers are able to take advantage of data in this way. One recent study of retail executives found that only 17% of respondents felt equipped to run live scenarios during planning meetings. Over half said their planning process was only “somewhat effective”, while most also admitted to spending more time collecting data than understanding and interpreting results.

The pandemic has shaken faith in demand prediction, not least by exposing the gap between how consumers are predicted to respond to unexpected change and how they do in reality.

In truth, demand understanding is just one part of the equation. Supply chain responsiveness is also critical.

We see the smartest retailers focus on being aligned, adaptable and agile — making greater use of data to:

- Align key parties across the network to the current market context, the needs of specific channels and relevant sales/purchase switch-patterns rather than just quantities sold

- Build-in adaptability across all functions. For instance: appropriate diversification of supply base, mix of short/long lead time, reduced minimum order quantities, focus on essential products and rethinking safety stock planning

- Become more agile. Increase speed of response through automation and integration of key processes (i.e. automated alerts on supply problems or demand spikes could help retailers to respond to customer’s needs. Another example could be automated promotional activity on surplus stock, etc). Greater collaboration and breaking down silos where necessary

Leveraging data should be ongoing work, driving continuous improvement. Contemporary technologies such as artificial intelligence (AI) and machine learning (ML) will increasingly enable organizations to fully benefit from automated learning with feedback being baked into their systems and processes. As referenced earlier, the Ericsson survey highlighted that the focus of 60% of logistics professionals are using data and AI for preemptive logistics.

Establish end-to-end visibility at every layer

Just as risk mitigation, cost reduction and demand prediction all depend on data, they also depend on end-to-end visibility across all layers of the supply chain. And retailers’ current lack of visibility is hard to overstate. Indeed, according to Frost & Sullivan research, 84% of chief supply chain officers identify a lack of visibility as their biggest challenge.

Generally speaking, this is because of the multi-party nature of supply networks and reliance on outsourced services; which, in turn, means challenges around sharing of data, due to factors such as poor integration across disparate systems and conflicting business interests. Establishing visibility and integrating contextual information can bring many benefits.

Issues can be spotted in real-time, whether they’re related to supplier fulfillment, workforce shortages, or customer delivery commitments. Equally, if any link in the supply chain is interrupted, your control or operations team can dive deep to identify not only the cause but which product lines and orders are going to be impacted, as well as the potential financial implications. Fundamentally, they can take smart action to mitigate the impact on the other layers.

Much like digital maturity, supply chain visibility often varies from function to function, with retailers struggling to create the cohesive contextual information matrix necessary for effective optimization. For example, let’s say your business model relies on fulfilling customers’ digital orders through a dark store. To optimize for customer outcomes and cost efficiency, visibility is required into everything from stock availability and pick capability to customers’ orders.

The truth is, the supply chain is no longer linear, but multidimensional. If products are to be in the right place at the right time, supply chain information must constantly be available across functions. Making smart decisions depends on digitizing supply chain data end-to-end and then making that data visible to planning teams in near-real time.

The key takeaways

For retail leaders, the great lockdown has focused both minds and agendas. It’s provided a clear mandate to:

- Align supply chain operations with wider corporate strategies

- Integrate supply chains with customer-facing functions, establishing common performance metrics that focus on fulfilling customer needs

- Structure supply chains to address local and global needs, and evolving regulations

- Invest in data infrastructure for end to end visibility and collaboration across the network

- Instill feedback loops and create a culture of continuous improvement.

While it’s no silver bullet, supply chain digitization will play a key role in helping retailers achieve these ambitions — and safeguard themselves against future crises, while driving continued commercial growth.

This article is the first in a series which focuses upon supply chain topics. Links to the subsequent pieces will be included here once they’ve been published.